Contract

Industries we serve

We do contracts in the following Industries:

Petro Chemical Industry

Petro Chemical Industry Bulk Drug & Pharmaceuticals

Bulk Drug & Pharmaceuticals  Chemical Industry

Chemical Industry Sugar Industry

Sugar Industry Power Plants

Power Plants

We undertake the following Industrial Cleaning Contracts on Turnkey basis:

- ♦ Heat exchangers tubes bundle inside cleaning

- ♦ Evaporator tubes cleaning

- ♦ Condensers tubes cleaning

- ♦ Boiler tubes cleaning

- ♦ Product pipe line cleaning

- ♦ Sewer pipe line cleaning

- ♦ Filter cleaning

- ♦ Surface preparation

- ♦ Sludge removal from oil storage tanks

- ♦ Cleaning of the plant during annual shut down

- ♦ Service & reconditioning of vehicle mounted systems (like Jet rodder, Gulper & Monster)

- ♦ Floor cleaning

- ♦ etc.

APPLICATIONS

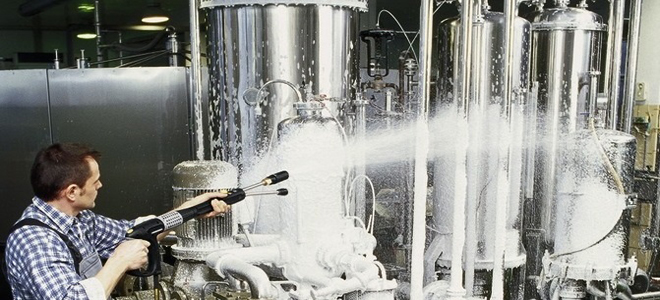

Comprehensive applications of hydro jet

Hydrojet's high-pressure water jetting systems are suitable for solving almost any problem related to industrial cleaning such as Surface preparation Pipe, Tube bundle cleaning Tank, Demolition De-scaling, De-greasing and De-burring. It is perfectly suitable for cleaning solutions in all industrial sectors.

Chemical, Petrochemical

- ♦ Internal cleaning of autoclaves, storage tanks, reactor vessels, agitators, crude oil tanks, distillation towers

- ♦ Cleaning tube bundles, cooling plant

- ♦ Decontamination, disinfection

- ♦ Pipe and drain cleaning

- ♦ Cleaning spray towers, dryers, filter stations

- ♦ Pressure testing vessels, pipelines, valves

- ♦ Cleaning production plant, vehicles, workshops etc.

“Service that is unparalleled,

With nothing less than your complete satisfaction”